Screw, Machine, Binding Head Steel Zinc Plated

| 46-208560P14 | |

| X-Ray | |

| GE HealthCare | |

| GE HealthCare | |

Enter your approval number and submit to add item(s) to cart.

Please enter approval number

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without the

approval number, GE will contact you before your order

can be confirmed for shipment.

Select your approver's name and submit to add item(s) to your cart

Please Select Approver Name

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without

selecting an approver, GE will contact you before your order

can be confirmed for shipment.

Product Overview

The Binding Head Stainless Steel Machine Screw is a specially designed component used in Signa advantage and other similar systems in X-Ray technology for demanding applications. The binding head screw has a type of head that is similar to the pan head but much thicker with a deeper slot. It is made up of high quality stainless steel material having good heat resistance, corrosion resistance and impact resistance which offers reliable operation, efficient functioning and longer life time and makes the product best fit for modern medical applications. The material also maintains excellent toughness and has more attractive appearance. The zinc coating electroplated on the surface adds an effective corrosion resistance to the material. The assembly is ROHS compliant and approved to the safety standards. The product is made from high-grade materials with good mechanical properties ensuring a Increased lifespan for the component. The high dimensional accuracy ensures a perfect fit of the parts as per the requirement and it is free from any burrs and sharp edges which enhances the safety aspect of the component. The GE product is an innovation and technology which fits well into versatile customer needs. It is manufactured using high precision techniques which helps to achieve a good surface finish as well as good product consistency. The part is diligently designed for high performance and reliability. It is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, Quality Assurance (QA) seal and shipment details.

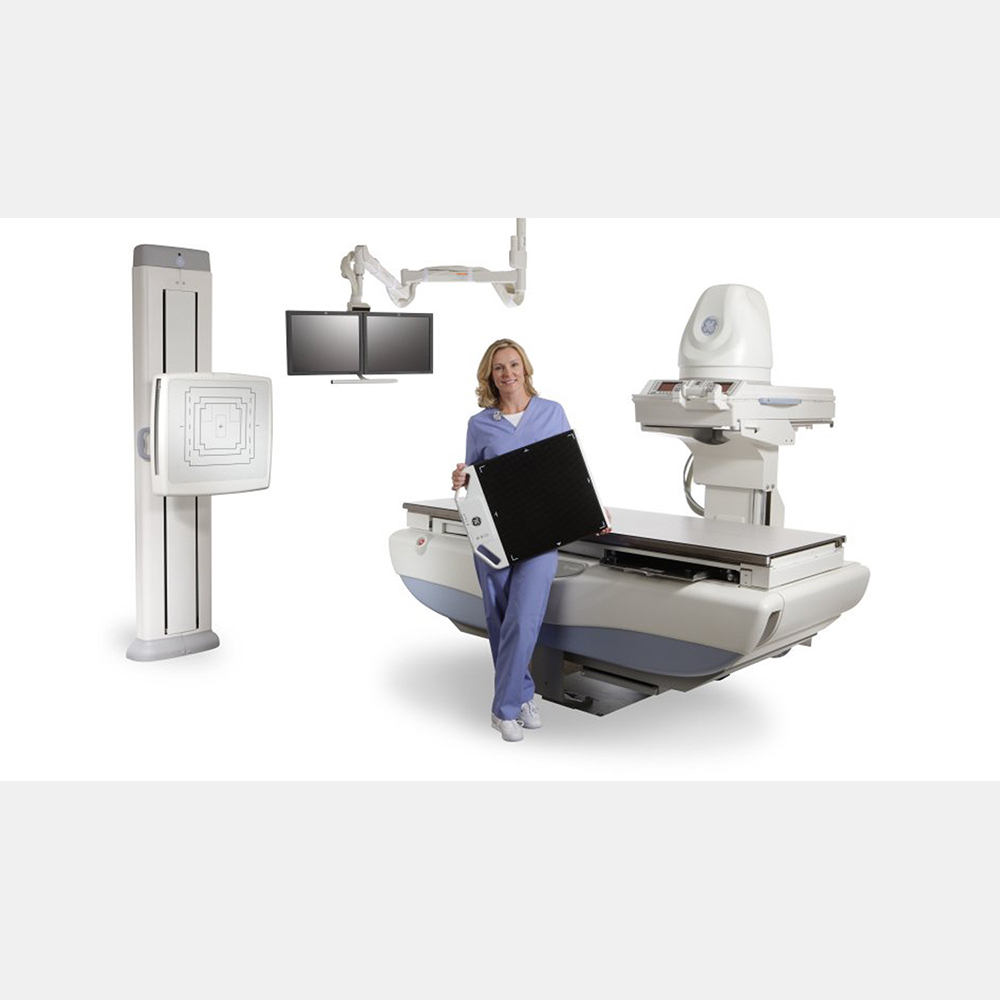

Compatible Products

Definium 8000

Precision 500D

Robust, digital performance at an efficient dose

It starts with the imaging chain, which features a 12-bit CCD-based camera.Then there’s AutoEx, which automatically adjusts key image-acquisition parameters in real time for optimum quality. Meanwhile, closed-loop Automatic Brightness Control and patented extended Dynamic Range circuitry maintain contrast and minimize blooming.

Definium AMX700

Revolution XRd