Vacuum Grease Dow Corning

| 46-252065P24 | |

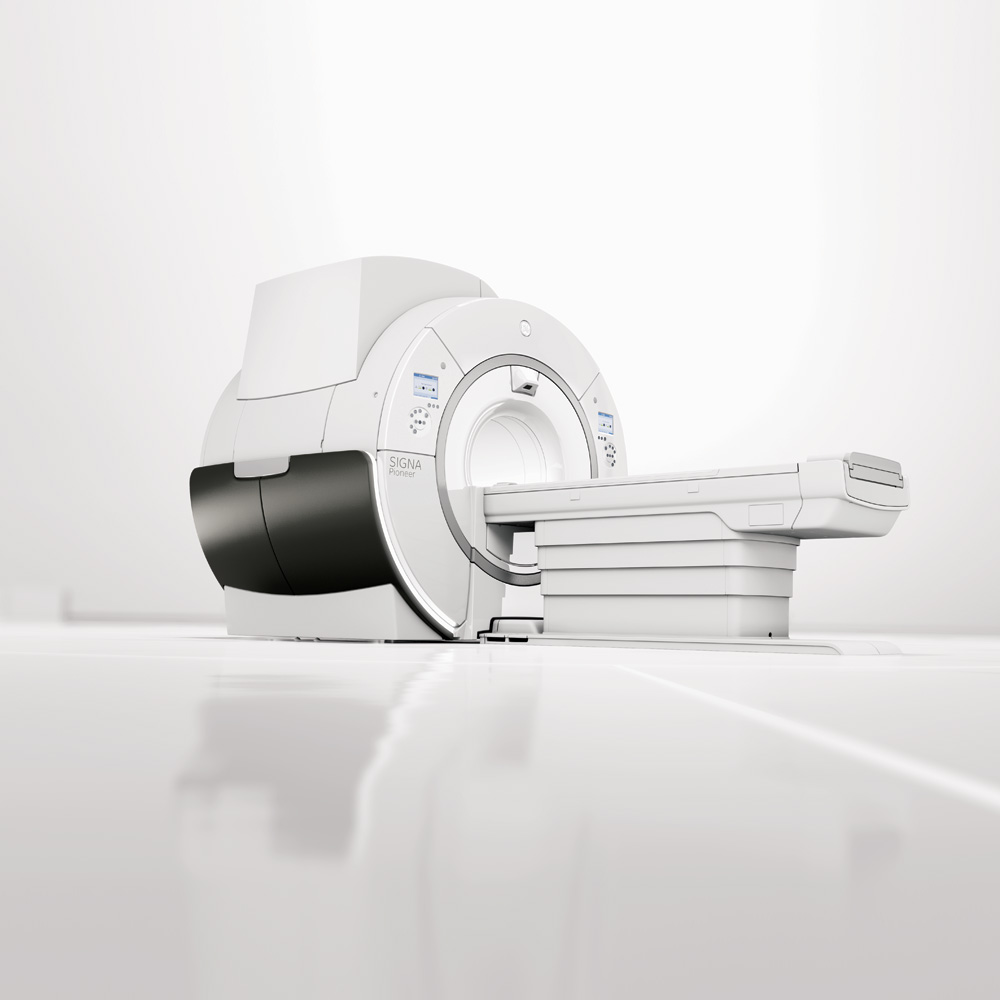

| Imagem por Ressonância Magnética (MRI) | |

| GE HealthCare | |

| GE HealthCare | |

Insira o seu número de aprovação e submeta para adicionar item (s) no carrinho.

Please enter approval number

OR

Não sabe o seu número de aprovação? Ligue para 800-437-1171

Enter opt 1 para os primeiros três avisos, e tenha o seu ID do Sistema disponível.

Se você adicionar item (s) no carrinho e enviar seu pedido sem o número de aprovação

, a GE irá contactá-lo antes que o seu pedido

seja confirmado para entrega.

Select your approver's name and submit to add item(s) to your cart

Please Select Approver Name

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without

selecting an approver, GE will contact you before your order

can be confirmed for shipment.

Visão geral do produto

The Dow Corning® High-Vacuum Grease is a stiff, Non-melting silicone lubricating material that maintains its consistency from -40 to 204° C (-40 to 400° F). It is used in applications similar to those for Dow Corning® Stopcock Grease and is the recommended replacement for that product. Dow Corning High-Vacuum Grease is recommended for vacuums reaching between 1 x 10-5 and 1 x 10-6 mm Hg. It is recommended that the grease be preconditioned under vacuum and temperature until these limits are reached. Dow Corning High-Vacuum Grease is supplied in 150-g (5.3-oz) tubes and 3.6-kg (8-Lb) pails, net weight. Dow Corning High-Vacuum Grease resists vegetable and mineral oils and common gases. It also resists aqueous solutions of inorganic salts and dilute acids and alkalis. Securing or including complete information on variables such as pressure, flow velocity, relubrication schedules and valve construction is impractical. For this reason, the suitability of Dow Corning High-Vacuum Grease should always be tested before the material is adopted for regular use. The GE product is an innovation which fits well into versatile customer needs. The part is diligently designed for superior performance and reliability. It is securely packed inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, Quality Assurance (QA) seal and shipment details.

Produtos Compatíveis

Brivo 355

Discovery 750w GEM 3.-T

Discovery 750 3.0T WU_0755

Optima 360 1.5T

Signa Creator 1.5T

Signa Excite 1.5T

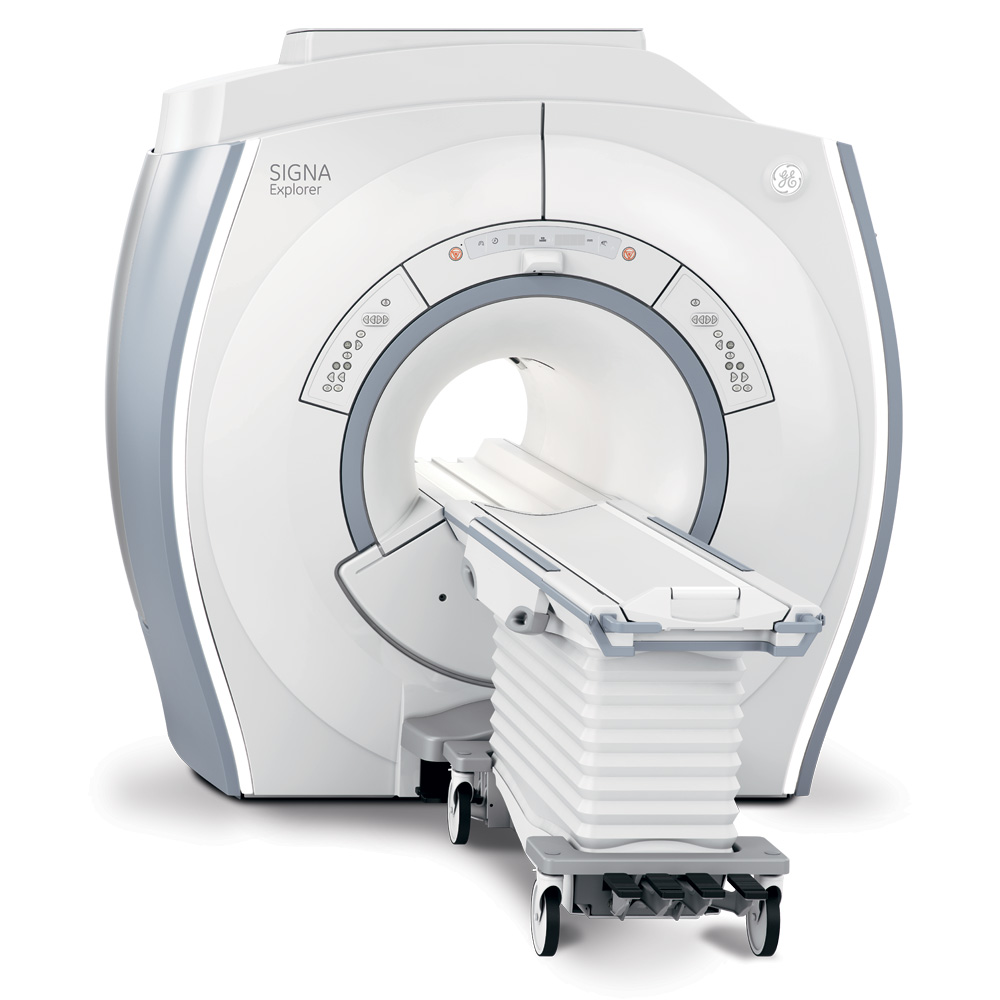

Signa Explorer 1.5T

Signa HD 1.5T

Signa HD 3.0T

Signa HDe 1.5T

Signa HDx 1.5T

Signa HDx 3.0T

Signa HDxt 1.5T

Signa HDxt 3.0T